- Multi-platform AR Human Machine Interface for Fabric Co-manipulation

In cases of sophisticated manufacturing operations, like composites layup, workers’ expertise is a valuable asset that cannot always be replaced. When operators are in the loop, it is integral to ensure the human centricity of the system towards its acceptance and efficient usage. To this direction, two key requirements must be met. Firstly, it isRead More…

In cases of sophisticated manufacturing operations, like composites layup, workers’ expertise is a valuable asset that cannot always be replaced. When operators are in the loop, it is integral to ensure the human centricity of the system towards its acceptance and efficient usage. To this direction, two key requirements must be met. Firstly, it isRead More… - Pioneering Collaborative Manipulation: The MERGING Model-based planning framework

The industrial landscape has been rapidly evolving, with robotics playing a pivotal role in shaping modern manufacturing and production processes. However, when it comes to handling flexible materials, the industry faces a unique set of challenges. These materials, due to their dynamic deformation, present complexities that are not encountered with rigid objects. Existing planning algorithms,Read More…

The industrial landscape has been rapidly evolving, with robotics playing a pivotal role in shaping modern manufacturing and production processes. However, when it comes to handling flexible materials, the industry faces a unique set of challenges. These materials, due to their dynamic deformation, present complexities that are not encountered with rigid objects. Existing planning algorithms,Read More… - Towards efficient composites manufacturing: A Multi-Purpose End-Effector for robotic layup

Automation in manufacturing has made leaps of progress in the last decades, revolutionizing industries across the globe. However, a persistent challenge still remains a headache for multiple industrial sectors – the handling of flexible objects. Nowhere is the challenge more pronounced than in composites manufacturing industry, which involves complex operations, from material handling to assemblyRead More…

Automation in manufacturing has made leaps of progress in the last decades, revolutionizing industries across the globe. However, a persistent challenge still remains a headache for multiple industrial sectors – the handling of flexible objects. Nowhere is the challenge more pronounced than in composites manufacturing industry, which involves complex operations, from material handling to assemblyRead More… - Fragile part comanipulation

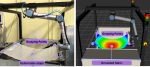

Large and fragile object manipulation tasks are extensively performed by operators in industrial contexts, for instance in aerospace industry as well as in construction field. Our work in the project has been driven by VDL use-case, dealing with the manufacture of composite parts. The manufacturing process of such parts requires the transport of large andRead More…

Large and fragile object manipulation tasks are extensively performed by operators in industrial contexts, for instance in aerospace industry as well as in construction field. Our work in the project has been driven by VDL use-case, dealing with the manufacture of composite parts. The manufacturing process of such parts requires the transport of large andRead More… - Multimodal teaching by demonstration

Historically, robotic arms have been applied mainly to large scale processes and production lines, with many smaller scale activities remaining largely based on manual work. The resulting robotic cells are generally fully autonomous, process is totally deterministic and locked, and no interaction is possible between operator and the robotic system during the execution. As aRead More…

Historically, robotic arms have been applied mainly to large scale processes and production lines, with many smaller scale activities remaining largely based on manual work. The resulting robotic cells are generally fully autonomous, process is totally deterministic and locked, and no interaction is possible between operator and the robotic system during the execution. As aRead More… - Data based solution for Complex Materials robotic manipulation

The challenge of manipulating complex materials involves the identification of measurable quantities that offer insights into the system, which can then be utilized to make informed decisions and take appropriate actions. This essentially involves combining a perception system with a decision-making process. Markov decision processes (MDP) are well-suited to address the task of defining optimalRead More…

The challenge of manipulating complex materials involves the identification of measurable quantities that offer insights into the system, which can then be utilized to make informed decisions and take appropriate actions. This essentially involves combining a perception system with a decision-making process. Markov decision processes (MDP) are well-suited to address the task of defining optimalRead More… - Optimizing modelling and simulation parameters for accurate digital representation of flexible materials

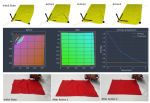

In today’s rapidly evolving industrial landscape, digitalization has emerged as a driving force behind the transformation of factories worldwide. Industries are increasingly harnessing the power of simulations and digital twins to revolutionize their manufacturing processes. One area of particular interest is the adoption of simulations and digital twins to drive digitalization efforts in industries dealingRead More…

In today’s rapidly evolving industrial landscape, digitalization has emerged as a driving force behind the transformation of factories worldwide. Industries are increasingly harnessing the power of simulations and digital twins to revolutionize their manufacturing processes. One area of particular interest is the adoption of simulations and digital twins to drive digitalization efforts in industries dealingRead More… - Advancing Deformable Material Modelling: Empowering Robotics and Simulation

The realm of robotics and simulation has witnessed a rapid evolution in recent years, marked by breakthroughs in areas like artificial intelligence, machine learning, and advanced material modelling. Still, handling and manipulating deformable materials, particularly fabrics, continue to present significant challenges. These materials exhibit complex behaviors due to their flexible nature and the diverse physicalRead More…

The realm of robotics and simulation has witnessed a rapid evolution in recent years, marked by breakthroughs in areas like artificial intelligence, machine learning, and advanced material modelling. Still, handling and manipulating deformable materials, particularly fabrics, continue to present significant challenges. These materials exhibit complex behaviors due to their flexible nature and the diverse physicalRead More… - Human perception for hybrid environments

Deploying robotized solutions in hybrid workspaces has been hindered by safety concerns for the past decade. Current solutions like physical barriers, safety monitoring systems, and wearable sensors are costly and require significant resources. To overcome this barrier, new approaches using artificial intelligence (AI) are needed to enable safe and natural human-robot interaction. The recent improvementsRead More…

Deploying robotized solutions in hybrid workspaces has been hindered by safety concerns for the past decade. Current solutions like physical barriers, safety monitoring systems, and wearable sensors are costly and require significant resources. To overcome this barrier, new approaches using artificial intelligence (AI) are needed to enable safe and natural human-robot interaction. The recent improvementsRead More… - Orchestrating complex robotic behaviors in flexible manufacturing systems

Modern manufacturing lines need to be more flexible and flexible systems require more complex orchestration strategies Smaller product lifecycles require recurrent changes either on the bill of resources, their layout arrangement, or their program routines. Subsequently, there is a need for manufacturing lines to be flexible while also balancing quality, productivity and cost. A reconfigurableRead More…

Modern manufacturing lines need to be more flexible and flexible systems require more complex orchestration strategies Smaller product lifecycles require recurrent changes either on the bill of resources, their layout arrangement, or their program routines. Subsequently, there is a need for manufacturing lines to be flexible while also balancing quality, productivity and cost. A reconfigurableRead More…