Many manufacturing sectors have been transformed by robots, which have become essential for industries such as automotive, assembly and others. However, some sectors are still reluctant to adopt automation, even though they could also benefit from it.

One of the selected use cases for MERGING, a European research project on soft robotics manipulation, coordinated by CEA and involving 11 partners from industry and academia, is the textile industry. It is a good example of a sector that could benefit from automation, but faces huge challenges in handling textile materials. For the European clothing sector, innovation through automation could be a way to boost competitiveness and reduce outsourcing, but most manufacturing processes are still manual and often outsourced to countries with low labor costs. This leads to a trade deficit for Europe, which exports € 61bn worth of textile products, but imports € 109 bn. Automation could help reverse this trend.

Textile and clothing are vital for the European economy, with around 160,000 companies employing over 1.5 million workers and generating a turnover of 162 billion euros.

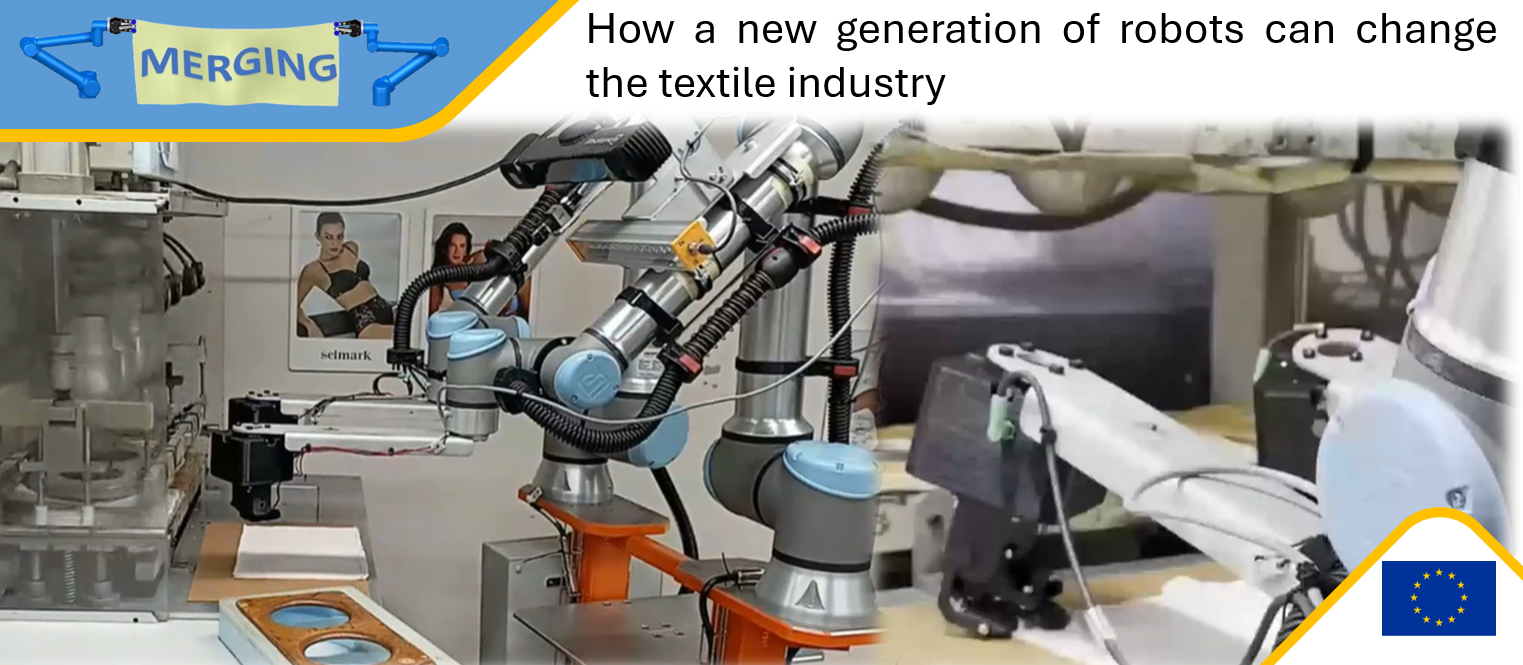

A robotic system that can assist human operators in the most tedious and exhausting tasks before the final product is stitched has been developed by researchers and engineers from various institutions within MERGING, a European research project on soft robotics manipulation. They have been working with SELMARK, a leading lingerie manufacturer based in Vigo (Spain).

The robots are responsible of taking textiles from the storage, then grabbing, placing and measuring them while preventing them from wrinkling. These operations are not feasible for traditional robotic manipulators designed for rigid objects, as they cannot easily adjust in real time to the unpredictable behavior of fabric. By automating these tasks completely or partially, personnel can be assigned to tasks that have more value added.

The MERGING solution comprises a pair of collaborative robot arms designed to operate safely alongside human workers. These arms are equipped with grippers developed by OMNIGRASP that utilize electroadhesion technology, leveraging electric fields to make objects adhere to their end-effectors. This feature enhances their ability to handle objects effectively. Additionally, AIMEN provides stereo vision technology, enabling precise perception and real-time tracking of textiles, allowing the robot’s movements to be adjusted as needed. CEA’s multi-modal programming by demonstration allows even inexperienced users to instruct the robot on task execution.

For high-level coordination, LMS’s Workcell Controller is employed to ensure runtime synchronization and monitoring of the execution process. Within SELMARK’s implemented robotic system, the robot arms carefully pick fabrics from a stack of textile materials, gently separating each layer from those below it. Subsequently, each ply is placed onto the thermoforming press, with the perception system promptly notifying if any wrinkles are detected. This integrated solution aims to enhance working conditions by assigning operators to less repetitive, more value-added tasks.

MERGING started in late 2019 and, within its four-year duration, it has worked on the implementation of innovative modules in the areas of handling, perception, cognition, and programming. Among others, the integrated demonstrator at SELMARK facilities consists of a benchmark not only for the robotics community but also for the textiles industry.

For more information: merging-project.eu

Media contact: andronas@lms.mech.upatras.gr

This project has received funding from the European Union’s Horizon 2020 research

and innovation programme under grant agreement No 869963